Gear

Si Woo Kim’s golf bag is one-of-a-kind. Just like him | Bag Spy

Si Woo Kim is one of the Tour’s most underrated personalities. His golf bag was created the same way. Take a deep dive in this Bag Spy.The 8 hybrids and utility irons our staff loved during testing | Fully Fit 2026

After six full-bag fittings at each of the major club makers, these are the hybrids our Fully Fit 2026 panelists chose for their bags.Cobra brings great vibes and new 3DP irons | Fully Fit 2026 Ep. 4

For the fourth day of Fully Fit 2026, the Cobra team brought out its new 3DP irons, OPTM metalwoods — and great vibes.The 6 fairway woods and mini drivers our staff loved during testing | Fully Fit 2026

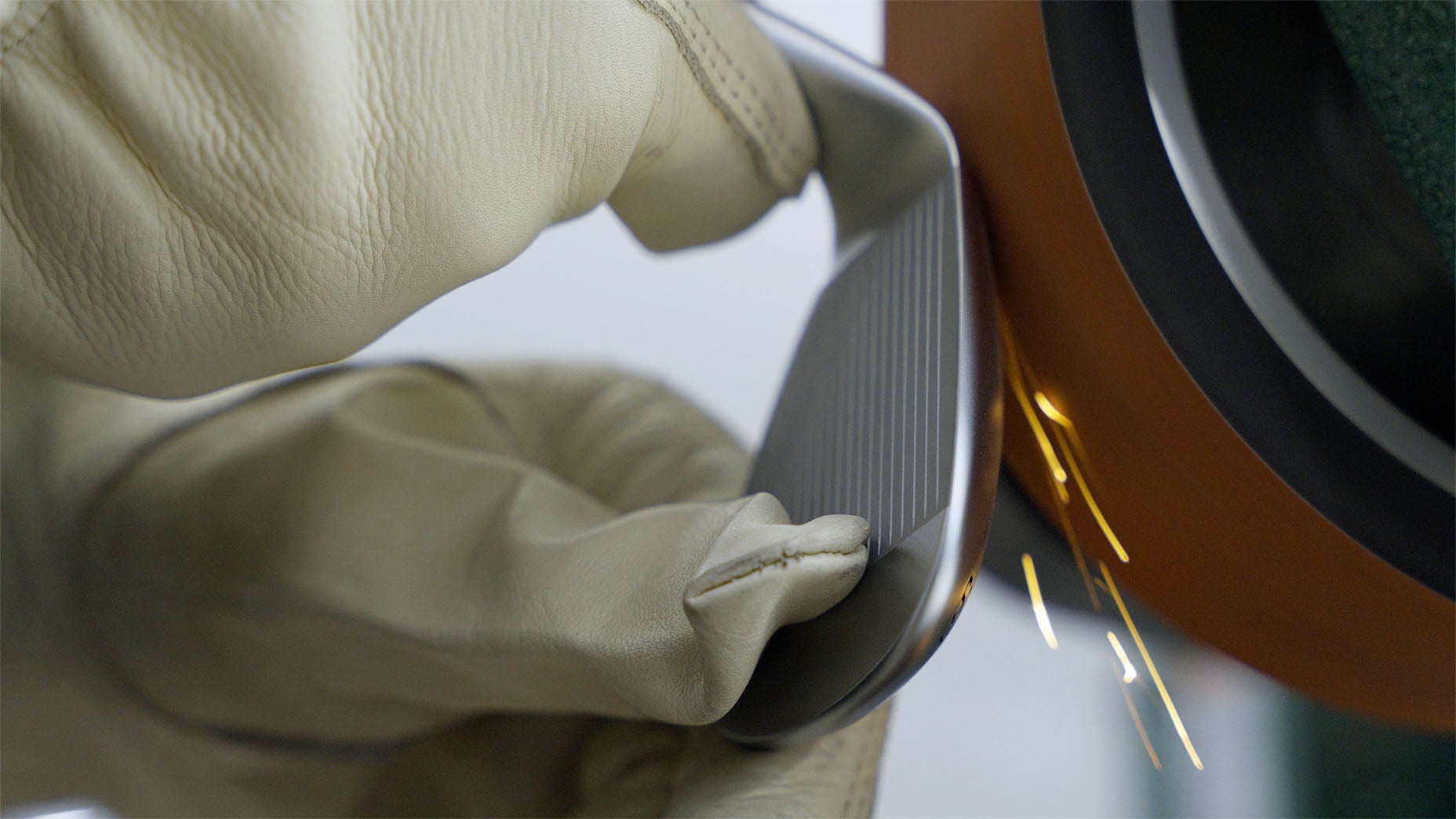

After six full-bag fittings at each of the major club makers, these are the fairway woods our Fully Fit 2026 panelists chose for their bags.Titleist shows off TPI, SM11 wedges, Scotty Cameron putters | Fully Fit 2026 Ep. 3

On Day 3 of Fully Fit 2026, the team heads to the Titleist Performance Institute for a full day of fittings for new Titleist clubs and balls.The 6 drivers our staff loved during testing | Fully Fit 2026

After six full-bag fittings at each of the major club makers, these are the drivers our six Fully Fit 2026 panelists chose for their bags.TaylorMade’s Qi4D driver, Spider putters steal the show | Fully Fit 2026 Ep. 2

On Day 2 of Fully Fit 2026, the gang heads to TaylorMade for fittings with their new Qi4D driver and popular Spider putter line.How 5 days of club fittings changed my mind on golf equipment | Fully Fit 2026

I went to golf equipment school for five days. Here’s what I learned on that journey, and what I think about clubs now.MORE DRIVERS

MORE IRONS

Join InsideGOLF today!

For only $39.99/year, you’ll get access to exclusive content and also a host of discounts and promotions, including…

- AD-FREE Experience on GOLF.com

- FREE Dozen Srixon Golf Balls

- $20 Instant Credit at Fairway Jockey

- One Year (8 issues) of Golf Magazine (+$79 Newsstand value) – U.S. members Only

- +600 Issue Golf Magazine Digital Archive (1959-Present)

- Bucket-List golf trips and experiences

- FREE True Spec Fitting with any club purchase

- $100 OFF qualified purchases at Miura and Fairway Jockey

- 50% OFF new Golf Logix App/membership

- Plus so much more!